Pressure Gauge Calibration Service

Pressure Gauge Calibration Services | VayomTech

Accurate Pressure Readings Start with Precision Calibration

At VayomTech, we specialize in professional pressure gauge calibration services to ensure your equipment delivers accurate and reliable pressure readings. With years of expertise and state-of-the-art calibration tools, we help industries maintain compliance, improve safety, and reduce downtime.

Whether you’re in manufacturing, pharmaceuticals, oil & gas, HVAC, or food processing, we understand the critical importance of properly calibrated pressure instruments. Our ISO-compliant calibration process ensures your gauges meet industry standards and perform consistently under varying conditions.

Why Choose VayomTech for Pressure Gauge Calibration?

Accurate, traceable calibrations

Quick turnaround time

On-site and in-house services available

Experienced technicians

Calibration certificates provided

Competitive pricing

Pressure Gauge Calibration: Why It Matters and How It’s Done

Pressure gauge calibration is a critical process that ensures your pressure measuring instruments deliver accurate, reliable, and repeatable readings. Whether you’re working in manufacturing, oil & gas, pharmaceuticals, or any other industrial sector, regular calibration of pressure gauges is essential for operational safety, product quality, and regulatory compliance.

In this article, we’ll explore what pressure gauge calibration is, why it matters, how it’s performed, and how often you should calibrate your pressure gauges.

What Is Pressure Gauge Calibration?

Pressure gauge calibration is the process of comparing the readings of a pressure gauge to a known, traceable reference standard. This ensures the pressure gauge is measuring correctly within its specified tolerance range.

Calibration involves:

Checking the accuracy of the pressure reading

Making adjustments if the readings deviate from the standard

Providing a calibration certificate as proof of accuracy

Why Is Pressure Gauge Calibration Important?

1. Ensure Safety

Inaccurate pressure readings can lead to dangerous over-pressurization or under-pressurization, risking equipment failure, leaks, or even explosions.

2. Meet Compliance Standards

Regulatory bodies such as ISO, FDA, ASME, and others require regular calibration of measuring instruments as part of quality assurance protocols.

3. Reduce Downtime and Costs

Calibrated gauges help detect potential issues early, reducing the risk of unexpected equipment failures and expensive repairs.

4. Maintain Product Quality

Accurate pressure measurements are vital in processes such as sterilization, blending, and packaging. Calibration ensures consistency and quality.

How Is Pressure Gauge Calibration Performed?

At VayomTech, we follow a structured, ISO-compliant calibration process:

Step 1: Pre-Inspection

We inspect the gauge for physical damage, dirt, or signs of wear.

Step 2: Apply Known Pressure

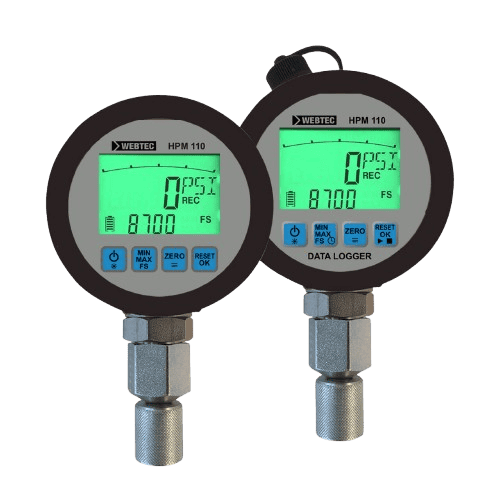

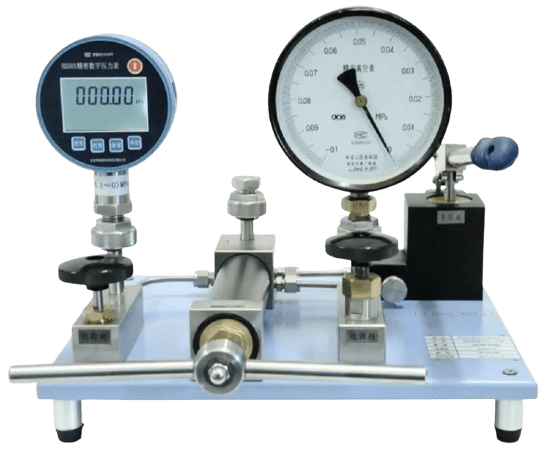

The gauge is tested using a calibrated pressure standard such as a deadweight tester or digital calibrator.

Step 3: Compare Readings

We compare the gauge’s readings to the known standard at multiple pressure points (e.g., 0%, 25%, 50%, 75%, 100%).

Step 4: Adjust (If Needed)

If the gauge is out of tolerance, we adjust it to bring it back within the acceptable range.

Step 5: Certification

After calibration, we issue a calibration certificate showing the measured values, tolerance, and traceability to national or international standards.

Types of Pressure Gauges That Require Calibration

Analog pressure gauges

Digital pressure gauges

Differential pressure gauges

Vacuum gauges

High-pressure gauges

Test and reference gauges

Each of these gauges has unique applications and accuracy requirements, which is why expert calibration is essential.

How Often Should You Calibrate Pressure Gauges?

Calibration frequency depends on several factors:

Manufacturer’s recommendations

Industry regulations

Environmental conditions

Frequency of use

Previous calibration results

As a rule of thumb, most industries calibrate pressure gauges annually, though critical applications may require more frequent calibration (e.g., quarterly or semi-annually).

On-Site vs. Laboratory Calibration

At VayomTech, we offer both in-house calibration at our lab and on-site calibration services. On-site calibration is ideal for facilities with minimal downtime allowances or fixed installations.

Trust VayomTech for Reliable Pressure Gauge Calibration

With advanced calibration equipment and highly trained technicians, VayomTech provides traceable, accurate, and reliable pressure gauge calibration services tailored to your industry needs.

ISO-compliant procedures

Fast turnaround

Detailed calibration reports

Affordable and flexible plans

Get in touch today to schedule your pressure gauge calibration or request a quote.

✆ Call: 9205804380 Email: sales@vayomtech.com

🌐 Website: www.vayomtech.com

Keywords included: pressure gauge calibration, pressure gauge calibration service, why pressure gauge calibration is important, how to calibrate pressure gauge, pressure gauge calibration frequency, types of pressure gauges, comark manometer calibration, comark pressure gauge calibration, comark diffrential maometer calibration, comark manometer calibration

Message Us

Find Us

- Address

- O-662/A, Amar Market, Jaitpur, Delhi 110044

- Email: sales@vayomtech.com

- Call: 9205804380

Pages

Recent Posts