Stack Height Calculation for DG Sets to ensure effective dispersion of exhaust emissions and to comply with the regulations. Stack height is a critical consideration when installing diesel generator sets (DG sets) to ensure effective dispersion of exhaust emissions and to comply with environmental regulations. The stack height of DG sets plays a significant role in minimizing the impact of pollutants on air quality and human health. The following factors influence the determination of stack height for DG sets:

To calculate the stack height for DG sets, dispersion modeling tools and software are often used, which take into account the above factors to estimate the appropriate stack height required for effective dispersion of emissions. It is essential to consult with air quality and environmental experts or regulatory authorities to ensure that the stack height complies with local regulations and minimizes the impact of emissions on nearby areas and public health. Properly calculated stack height and effective dispersion of emissions are essential for maintaining good air quality and mitigating the potential adverse effects of diesel generator operation on the environment.

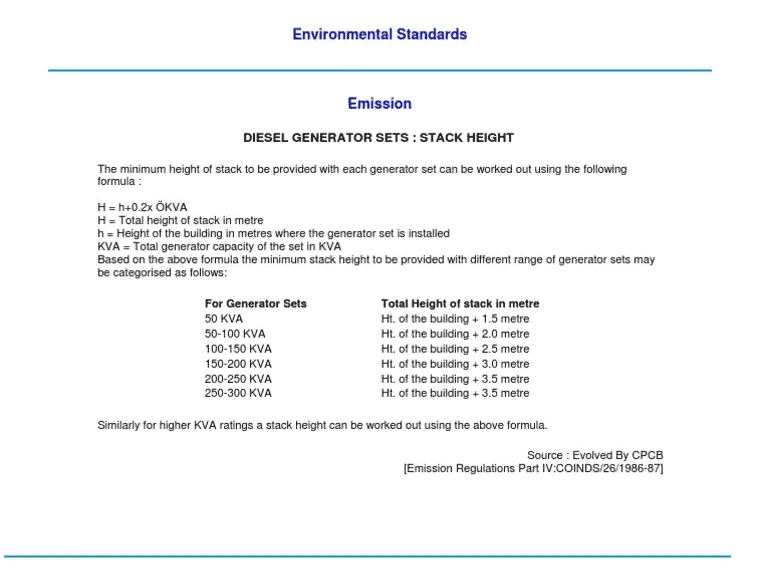

DG Set Height Calculation formula as per Source: CPCB Emission Regulation Part IV

Calculating Stack Height of DG sets For A Facility:The minimum height of stack to be provided with each generator set can be worked out using the following formula :

H = h + 0.2 x √ KVA

30 m High or 3 m above the building height, which ever is higher.

Where:

H = Total height of stack in meter

h = Height of the building in meters where the generator set is to be installed

KVA = Total generator capacity of the set in KVA

This is an explicit formula for DG SET stack height calculation, irrespective of the type of industries where the generator set is installed.

Based on the above formula the minimum stack height to be provided with different range of generator sets may be categorized as follows:

| For Generator Sets | Total Height of stack in meter |

| 50 KVA | Ht. of the building + 1.5 meter |

| 50-100 KVA | Ht. of the building + 2.0 meter |

| 100-150 KVA | Ht. of the building + 2.5 meter |

| 150-200 KVA | Ht. of the building + 3.0 meter |

| 200-250 KVA | Ht. of the building + 3.5 meter |

| 250-300 KVA | Ht. of the building + 3.5 meter |

For DG Set above 1000KVA, minimum stack height should be 30 m. Dg set exhaust port should be atleast 3m above the building where it is placed. So that total stack height should be 30m or more.

For example if a building is 25m high, then dg set stack exhaust port should be 5m. So total stack height will be 30m.

Another example if building height is 32m, then dg set stack exhaust port should be 3m above the building, so total stack height will be 35m.