Stack Monitoring Kit VTSS1

VYOMTECH STACK MONITORING KIT VTSS1 is scientifically designed instrument. It can be used to measure total emission of Particulate Matter and Gaseous Pollutants from all types of industries including Thermal power stations, Steel Plants, Chemical Plants and Cement Industry. VTSS1 is a manual stack monitoring kit or stack sampler.

Our Portable Stack Monitoring Kit VTSS1 can be used to take accurate representative samples of Particulate Matter and various Gaseous Pollutants like SO2, NOx, etc from the stack in accordance with the methodologies developed by USEPA and as specified by Central Pollution Control Board in Emission Regulation.

Features of Stack Monitoring Kit VTSS1

- Portable, Compact & Light Weight Instrument

- Zero Leak Check Facility

- User Friendly & Easy to Operate

- Best Quality instrument for long operating life.

- 1 Year Manufacturing Warranty

- Digital Display for Ambient & Stack Temperature

- Digital Manometer for Differential Pressure

- Portable Stack Sampler Design

Stack Monitoring Kit Specifications

|

Stack Temperature Range |

Ambient to 600 deg C read on a Digital Pyrometer |

|

Stack Velocity Range |

Up to 60 m/sec |

|

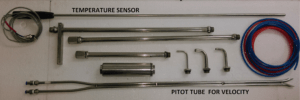

Thermocouple |

K-Type Thermocouple made of SS304, 0.6 Mtr long. |

|

Manometer |

Digital with 0-1000 mm of H20 range |

|

Pitot Tube |

Calibrated S-type made of SS 304, 0.6 m extendable to 1.2m |

|

Particulate Sampling |

0-30 LPM collection on thimble type filter up to 0.3 micron rating |

|

Gaseous Sampling |

0-3 LPM collection in a set of glass impingers |

|

Rotameter |

Acrylic body with 2% FSD accuracy, 0-30 lpm PM and 0 – 3 lpm for GAS |

|

Sampling Probe |

Made from SS 304 tube, 0.6 m length extendable to 1.2m |

|

Filter Holder |

Fabricated from SS 304 tube suitable to hold either cellulose filtration thimble (Size 28mm 10 X 100 mm long) or glass micro fibre thimble (size19mm ID X 90mm long) |

|

Nozzles |

A Set of 3 SS304 Nozzles (1/8, 1/4 & 3/8 Inch) |

|

Digital Clock |

0-60 minutes, 1 second readout with start and stop switches |

|

Sampling Train |

1 No. of 240 ml & 2 No. of 120 ·ml glass impingers accommodated in ice tray, placed on the rear side of instrument panel with a provision to keep ice. |

|

Vacuum Pump |

Oil Free Vacuum Pump with Free Flow of 60 LPM, single phase 220V Supply. |

If you require assistance with the stack monitoring kit, whether it’s the manual, technical inquiries, or pricing details, we’re here to help. Our team is dedicated to ensuring you have all the information you need to make the most of our products.

We understand that navigating technical specifications and product features can sometimes be challenging, so we encourage you to reach out with any questions or concerns you may have. Whether you’re looking for guidance on installation, troubleshooting, or general usage of the stack monitoring kit, our knowledgeable staff is ready to provide support.

Additionally, if you’re interested in pricing options or would like a quote, please let us know. We strive to offer competitive pricing and value for our customers, and we’re happy to discuss your needs in detail.

You can also contact us via email at sales@vayomtech.com. Our email support team is responsive and can provide you with the information you need promptly. We value your interest in our products and look forward to assisting you.

Frequently asked Questions about Stack Monitoring

What is Stack Monitoring Kit ?

Stack Monitoring Kit is specially designed instrument for measuring the total volumetric discharge of particulate matter and gaseous pollutants from the Boiler, DG stacks, Process outlets, Scrubber Outlets, etc

A portable stack sampler is used to measure the concentration of pollutants or gases emitted from industrial stacks or chimneys. It allows for on-site sampling, making it easier to collect representative samples without the need for complex, fixed sampling systems.

What is the purpose of Stack Sampling ?

The main objective of stack sampling is to determine the concentration of various pollutants released from the stack. The sample(s) analysed must be representative of the gas stream being tested. Therefore, the objective of the stack sampling technique is to ensure that the sampled gas stream is representative of either the total or a known portion of the source emissions.

What is Isokinetic Sampling ?

Basically, the idea is to sample at the same velocity as the gas stream so that the streamlines in the vicinity of the nozzle are straight. Isokinetic sampling techniques were developed to prevent wrong particulate concentration measurements due to inertial effects of particles as they enter a sampling nozzle.

Isokinetic sampling is a technique used to collect air or gas samples from stacks or ducts in a way that maintains the same velocity as the surrounding gas stream. This method ensures that the sample accurately represents the composition and concentration of the emissions being measured.

Key Features of Isokinetic Sampling:

Velocity Matching: The sampling probe is designed to match the velocity of the gas stream, preventing particle loss or alteration in the sample due to differences in flow rates.

Uniform Collection: By ensuring that the sample is collected at the same velocity, isokinetic sampling minimizes bias, leading to more accurate results.

Applications: It’s commonly used in environmental monitoring, emissions testing, and compliance assessments in various industries, including power generation and manufacturing.

Equipment: Isokinetic samplers often include specialized nozzles and flow measurement devices to ensure the correct sampling conditions.

By maintaining isokinetic conditions, this method helps produce reliable data that is crucial for assessing compliance with air quality regulations and understanding emission sources.

What is Stack Monitoring Kit is used for ?

The Stack Monitoring Kit is used for measuring the total volumetric discharge (emission) of particulate matter and gaseous pollutants from the stacks. It consist of: S.S. Thermocouple and digital temperature reading monitor: to read the stack gas temperature.

Why do you need stack monitoring?

Stack monitoring will determine the various pollutants beings released in the atmosphere and their levels. To conduct Stack monitoring in India CPCB (Central Pollution Control Board) have put forth guidelines and permissible limits.

What is stack monitoring report?

How do you calculate the stack height of a DG set?

Calculating Stack Height Of DG sets For A Facility:

The minimum height of stack to be provided with each generator set can be worked out using the following formula :

H = h+0.2 x √ KVA

Where:

H = Total height of stack in meter

h = Height of the building in meters where the generator set is to be installed

KVA = Total generator capacity of the set in KVA

This is an explicit formula for DG SET stack height calculation, irrespective of the type of industries where the generator set is installed.

Based on the above formula the minimum stack height to be provided with different range of generator sets may be categorized as follows:

| For Generator Sets | Total Height of stack in meter |

| 50 KVA | Ht. of the building + 1.5 meter |

| 50-100 KVA | Ht. of the building + 2.0 meter |

| 100-150 KVA | Ht. of the building + 2.5 meter |

| 150-200 KVA | Ht. of the building + 3.0 meter |

| 200-250 KVA | Ht. of the building + 3.5 meter |

| 250-300 KVA | Ht. of the building + 3.5 meter |

Message Us

Find Us

- Address

- O-662/A, Amar Market, Jaitpur, Delhi 110044

- Email: sales@vayomtech.com

- Call: 9205804380

Pages

Recent Posts